Bagaimana Mesin Pengering Berkelanjutan HH3 meningkatkan efisiensi pengeringan tekstil dan kapasitas produksi?

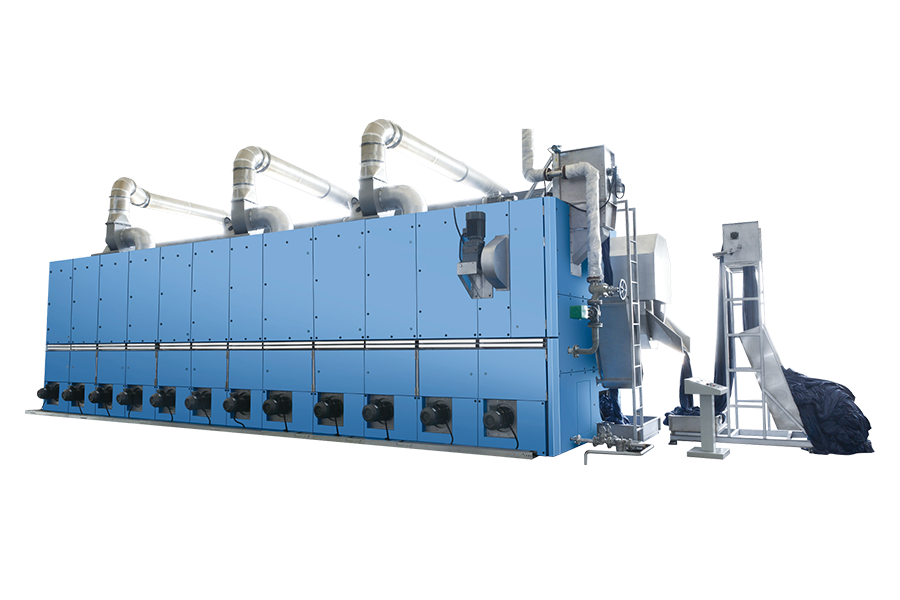

Itu Mesin Pengering Berkelanjutan HH3 menggunakan desain pengeringan drum kontinyu, menggantikan peralatan pengeringan vertikal tradisional. Hal ini secara efektif mengurangi pengoperasian manual sekaligus memungkinkan produksi berkelanjutan berkecepatan tinggi dan berkapasitas tinggi. Keunggulan utama mesin ini terletak pada sistem udara panas berenergi tinggi, yang mengeringkan kain basah dengan cepat dan merata hingga mencapai kondisi ideal, sehingga secara signifikan memperpendek siklus pengeringan.

Dibandingkan dengan peralatan tradisional, HH3 mempertahankan rasa lembut dan halus sekaligus mengontrol penyusutan dengan lebih baik. Desainnya yang bebas tegangan mencegah kain meregang selama proses pengeringan, mengurangi stres, dan meminimalkan risiko deformasi dan penyusutan. HH3 memastikan pengeringan seragam untuk berbagai jenis kain, termasuk katun, modal, linen, dan krep, sehingga meningkatkan kedalaman dan kenyamanan visual kain.

Dengan mengoptimalkan aliran udara panas dan kontrol suhu, mesin pengering juga mendukung relaksasi, pra-penyusutan, dan penggemburan, sehingga sangat cocok untuk kain rajutan stretch, sehingga secara efektif meningkatkan kualitas pemrosesannya. Secara keseluruhan, HH3 tidak hanya meningkatkan efisiensi produksi bagi perusahaan tekstil tetapi juga membantu mereka mencapai tujuan produksi yang ramah lingkungan, hemat energi, dan ramah lingkungan.

Itu Continuous Tumble Dryer HH3's high efficiency is reflected not only in its drying speed but also in its automated and intelligent control system. Equipped with advanced temperature sensors and humidity monitoring devices, the equipment monitors key parameters during the drying process in real time, ensuring that hot air temperature and humidity remain within optimal ranges, preventing over-drying or uneven drying of fabrics due to temperature fluctuations. This precise control significantly reduces manual adjustment errors and trial-and-error costs, improving the stability and consistency of the finished product.

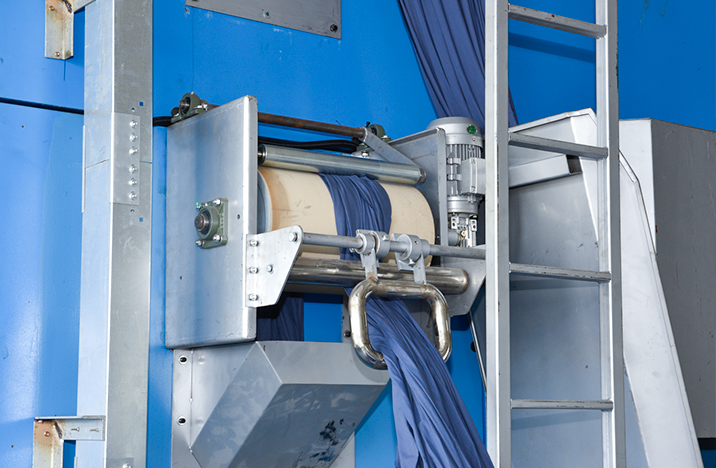

Itu HH3's continuous drum structure ensures that fabrics are constantly tumbled and heated evenly during the drying process, preventing over- or under-drying in certain areas. Its optimized hot air circulation path ensures that hot air fully penetrates the fabric, improving drying efficiency while protecting the fiber structure. This design not only ensures fabric softness and loft, but also significantly reduces energy consumption, meeting the energy conservation and emission reduction needs of the modern textile industry and helping companies achieve green manufacturing and sustainable development.

Teknologi canggih apa yang digunakan oleh Continuous Tumble Dryer HH3 untuk memastikan efisiensi pengeringan dan stabilitas peralatan?

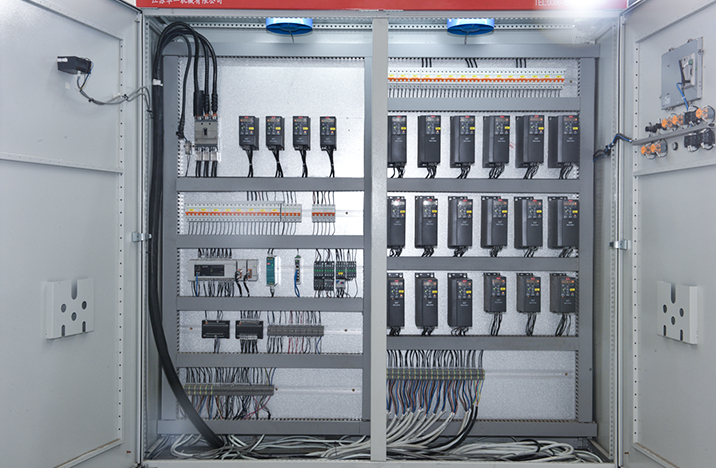

Itu Mesin Pengering Berkelanjutan HH3 dilengkapi dengan beberapa sistem kontrol elektromekanis canggih, memungkinkan kontrol suhu yang tepat dan manajemen otomatis untuk memastikan hasil pengeringan yang optimal untuk setiap batch kain. Radiator efisiensi tinggi dan filter dua lapis bawaan alat berat secara efektif menyaring kotoran dari udara, memastikan udara panas bersih dan mencegah kontaminasi kain.

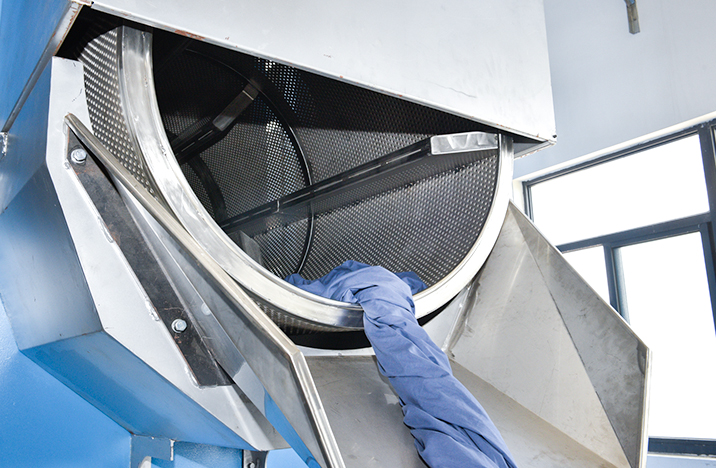

Itu 1100mm stainless steel drum and key components constructed from 304 stainless steel not only ensure corrosion resistance and longevity, but also provide a safe and hygienic processing environment for fabrics. The fabric lifter is strategically designed to ensure even fabric rotation within the drum, promoting sufficient contact between hot air and fabric, and improving drying uniformity.

Desain struktural ini menyeimbangkan efisiensi tinggi dengan stabilitas peralatan, mengurangi frekuensi pemeliharaan dan waktu henti, memastikan produksi berkelanjutan bagi perusahaan tekstil, meminimalkan risiko kegagalan, dan meningkatkan efisiensi lini produksi yang stabil.

Itu Continuous Tumble Dryer HH3's advanced electromechanical control system, utilizing intelligent PLC programming and a human-machine interface, enables real-time monitoring and precise adjustment of key parameters such as temperature, air speed, and conveyor speed. Operators can intuitively set drying process parameters via a touchscreen interface, and the system automatically records operating data for easy production tracking and quality management. This not only improves controllability of the drying process but also significantly reduces operational errors, enhancing production consistency and stability.

Itu equipment's high-efficiency radiator and double-layer filter system effectively ensure the purity of the hot air, preventing dust and impurities from contaminating the fabric surface and ensuring the quality of the finished product. This double-layer filter design not only improves filtration efficiency but also facilitates routine maintenance and replacement, reducing maintenance costs. Furthermore, the use of a large-diameter 1100mm stainless steel drum, combined with the strategically positioned fabric lifting wheels, ensures sufficient and even tumbling of fabrics during the drying process, enhancing hot air penetration and drying uniformity. The overall durability and stability of the design ensure excellent performance even under high loads, significantly improving production continuity and profitability for textile companies.

Bagaimana Continuous Tumble Dryer HH3 memenuhi kebutuhan pemrosesan beragam kain tekstil?

Itu textile industry encompasses a diverse range of fabrics, from natural fibers like cotton and linen to functional fibers like modal and stretch knits, and even high-end crepe and sofa fabrics. Each fabric presents distinct drying requirements. The Continuous Tumble Dryer HH3, with its flexible parameter settings and versatile processing capabilities, meets these diverse needs.

Itu device supports precise control of temperature, air speed, and conveyor speed, enabling customized drying solutions for different materials. For stretch knit fabrics, the HH3 effectively bulks and pre-shrinks them, preserving their elasticity and feel. For natural fibers, it maintains softness and breathability while avoiding brittleness or shrinkage caused by overdrying.

Itu HH3 is suitable for continuous batch production and can process large quantities of fabrics of varying specifications. It is widely used in apparel, home textiles, automotive interiors, and functional textiles. By integrating multiple technologies, the HH3 provides textile manufacturers with efficient, environmentally friendly, and versatile solutions, helping the industry reach new heights in intelligent and green manufacturing. The Continuous Tumble Dryer HH3's high flexibility is reflected not only in its parameter adjustment but also in its deep adaptability to the diverse characteristics of fabrics. For example, when processing high-end crepe and sofa fabrics, the machine optimizes hot air distribution and drum speed to effectively reduce wrinkles and deformation, preserving the fabric's original texture and visual appeal. Furthermore, for functional fibers such as modal and stretch knits, the HH3 allows for precise control of the drying rhythm to avoid fiber damage caused by over-drying, thereby ensuring fabric comfort and durability.

Itu HH3's continuous production capabilities make it particularly well-suited to the needs of modern, large-scale textile mills. Whether processing multiple mixed batches or alternating fabric specifications, the machine enables rapid switching and stable operation, significantly improving production efficiency. Combined with an advanced automated control system, the HH3 also enables remote monitoring and fault diagnosis, helping companies reduce labor costs and maintenance difficulties, driving textile manufacturing towards intelligent and digital development, and truly achieving efficient, environmentally friendly, and sustainable production goals.